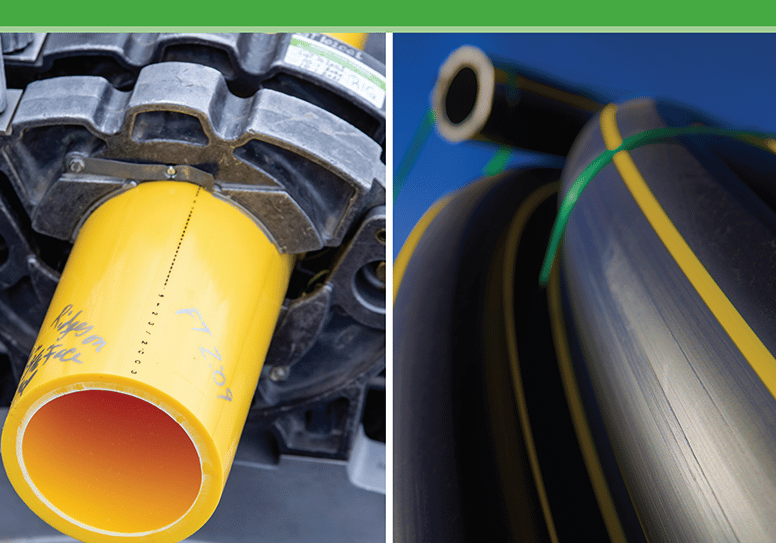

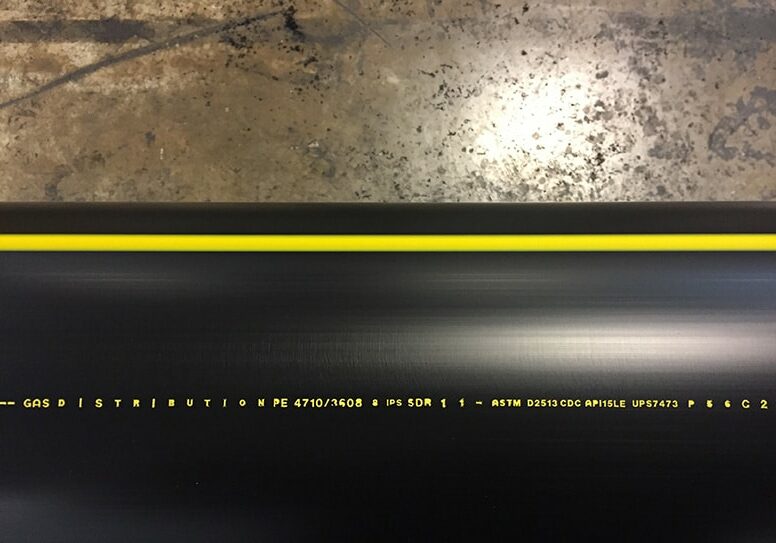

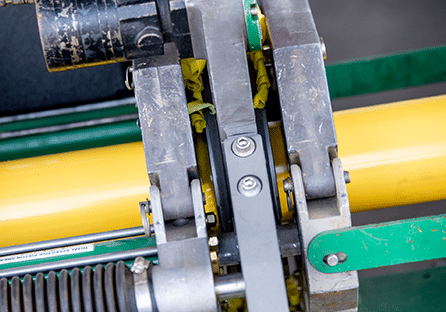

Polyethylene pipe is widely used in the energy market to transmit natural gas for cities and municipalities, transmit oil and natural gas from well sites to sales lines and in cross-country transmission lines. Our Stream-Line products can be used both onsite at oil and gas wells and for oil and gas transmission. We offer polyethylene pipe coil and reel options in multiple lengths to easily facilitate shipping and installation of long lengths of pipe required for oil and gas projects.

Products in the Stream-Line suite include high-density D2513 pipe for pressurized gas transmission, F2619 oil and gas gathering and transmission pipe, Hard-Line™ for high-pressure, high-corrosive and heavy wall applications, MDPE for medium-pressure gas transmission, PA-12 for regulated gas transmission and Sleeve-It! ™ for gas line protection.

Related Articles

Meeting Rising Water Demand for Mining

The mining industry is booming. Widespread electrification and the rise of renewable energy have led to increased demand for batteries, solar panels, and other products that rely on metals like lithium, cobalt, and nickel. Outside the auto and renewable energy industries, living standards are improving around the world, which leads to sustained demand for goods across a range of industries. For instance, higher standards of living coincide with increased demand for gold for consumer electronics, copper for electrical wiring, and iron to produce steel for construction materials, as well as lithium to power cell phones and laptops.

HDPE and Beyond

Plastic is an integral part of our daily lives, from the products we use to how those products are made and transported to us. Depending on the ultimate use, one type of plastic might be more beneficial than another; each type has its own unique properties that make it best suited for a given application.

HDPE Pipe ASTM Standards Guide: 16 Common Standards

ASTM International develops and publishes technical standards for several industries, including manufacturing, chemicals, consumer products, energy and utilities, and construction. The HDPE pipe manufactured by United Poly Systems adheres to all applicable ASTM standards.

Quote Your Project

Need a price for your project? We just need to know a bit about the job. Fill out the form to request a quote from our piping systems experts.

Minimum order length is based on pipe diameter. Please consult our Minimum Order Quantities guide before requesting a quote.