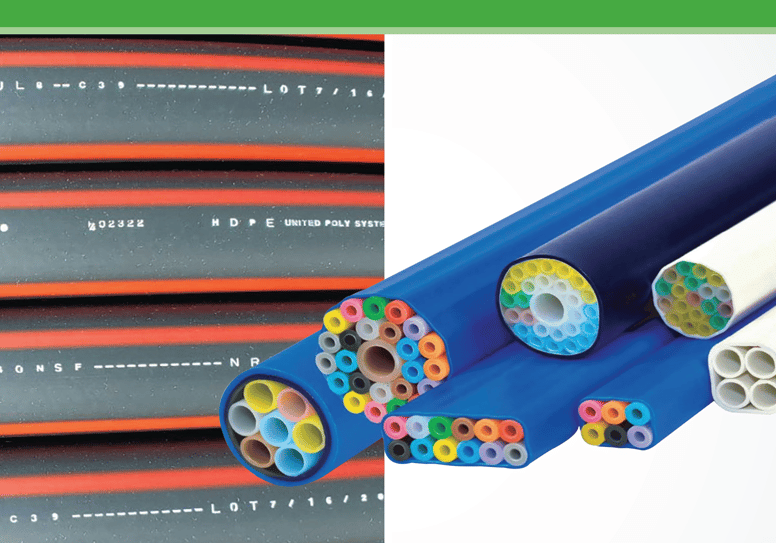

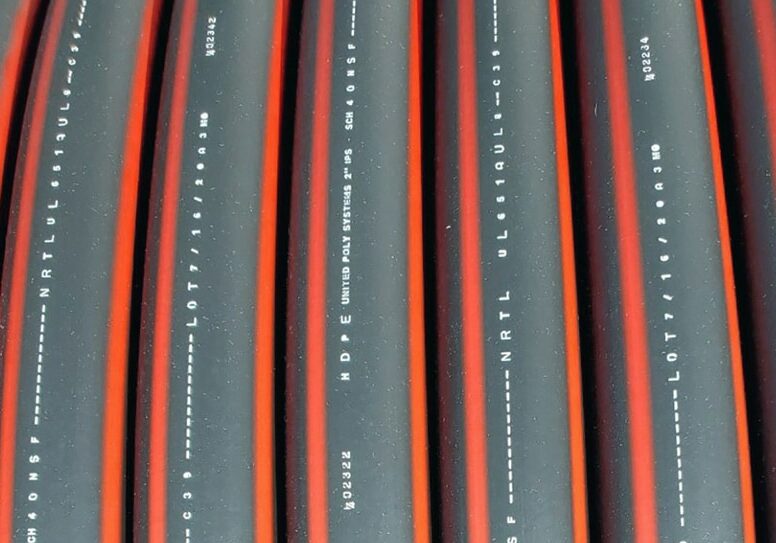

HDPE pipe is a flexible and versatile option for power and communications conduit. Conduit is used as a raceway to protect underground electrical, fiber optic and broadband cables from corrosive soil, wildfires, earthquakes, hurricanes, floods and tornadoes. We can customize conduit diameter, thickness, color, and other options to suit each project and can manufacture custom lengths to maximize footage and reduce connections. HDPE conduit can be installed via directional drilling, trenching, micro-trenching and plowing to suit each project’s needs.

Products in the Conduit suite include Comm-Line™ for telecommunications, Hard-Line™ for high-pressure, high-corrosive and heavy wall applications, MicroPath™ for microduct and microcabling, Power-Line™ for electrical and high-voltage lines, Pro-Line™ for PVC pipe replacement, and Sleeve-It!™ for gas line protection.

Related Articles

Electrical Grid Resilience: HDPE Conduit in Extreme Weather

As extreme weather events continue to intensify, our electrical grids are put to the test, revealing their vulnerabilities and the need for more resilient infrastructure. Unprecedented climate stress tests have exposed the weaknesses of traditional electrical systems, prompting a reassessment of the materials used in grid construction.

What is Middle Mile Infrastructure?

In today’s world, broadband internet is a fundamental utility for both businesses and families, providing access to essential services and opportunities. As the demand for high-speed internet continues to surge, the need for reliable and efficient infrastructure becomes increasingly important.

The Numerous Environmental Benefits of Microduct

Today’s world relies on digital solutions and reliable, gigabit-speed internet connections. The conduit systems that can support and protect delicate fiber cables are in high demand. Microduct, which has been used for decades in Europe and Asia, is quickly becoming the preferred choice for housing telecommunications and energy cables in the U.S. It is an integral part of maintaining a secure, fast, and reliable network in hospitals, businesses, and federal buildings. Further, upgrading to microduct can help schools promote and use remote learning.

Quote Your Project

Need a price for your project? We just need to know a bit about the job. Fill out the form to request a quote from our piping systems experts.

Minimum order length is based on pipe diameter. Please consult our Minimum Order Quantities guide before requesting a quote.